Pumps are devices designed to move fluids, such as liquids or gases, from one place to another. They play a crucial role in various industries, including manufacturing, construction, energy production, and more

We supply a wide range of Pumps, Electric Motors and Pump Systems, including all ancillary equipment such as Valves, Fittings, Controls, and more. Flow Tech General Trading supplies the following Pumps for Domestic and Industrial purposes such as Gear, Booster, Boreholes Pumps & Accessories, Self Prime Pumps, Centrifugal & Sewage.

“Great customer service, kuddos for supplying us with the right things the right way rather than the easy way. I am still getting compliments about the pumps solutions used for my very big project.”

WHAT THE PEOPLE SAY

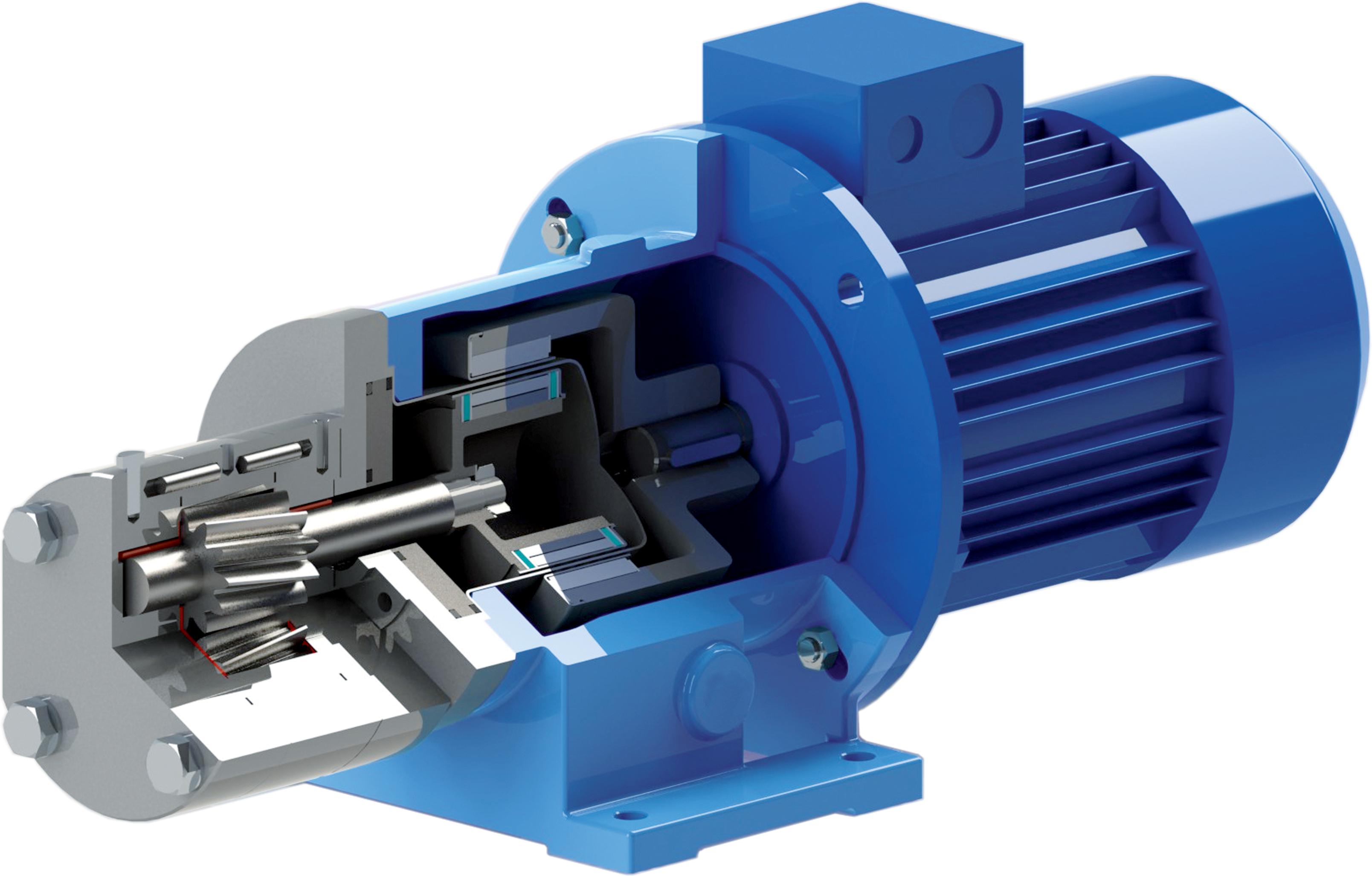

It operates by creating a sealed cavity between the gear teeth and the pump housing. Explosion Proof for Fuel Transfer.

These pumps are submerged in the water source and are specifically designed to handle the challenges of pumping water from considerable depths

Self-priming pumps are a type of centrifugal pump designed with the capability to evacuate air from the pump suction line and create a vacuum that allows the pump to draw fluid into the system and begin pumping without the need for manual priming.

Centrifugal pumps are a widely used type of dynamic pump that are designed to move fluids using the kinetic energy generated by a rotating impeller.

Sewage pumps are specialised pumps designed to handle the transport and disposal of wastewater and sewage containing solids, debris, and other contaminants. They play a critical role in municipal wastewater systems, industrial facilities, and residential applications by efficiently moving sewage from lower to higher elevations or through treatment processes.

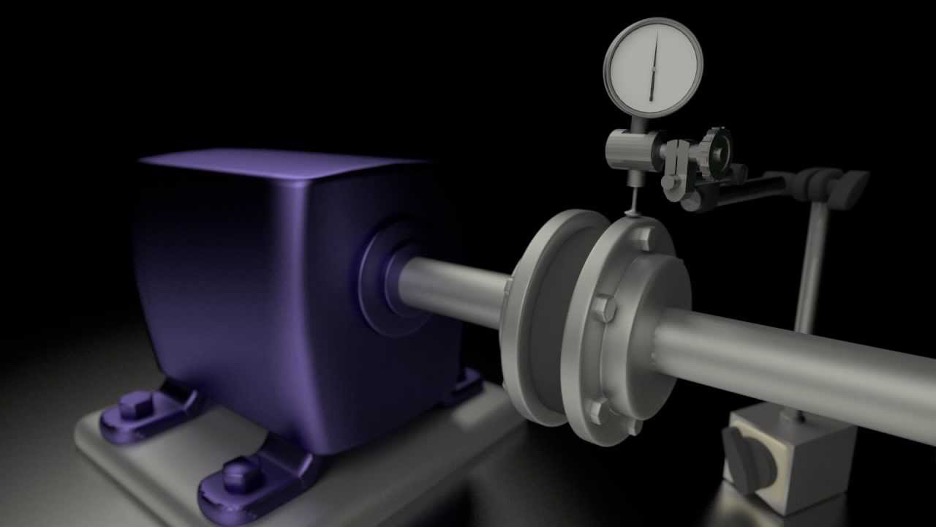

Motor-Pump alignment is the process of aligning shaft center lines between a motor and a pump. The motor is the prime mover, transferring power to the pump by the use of a coupling. This is probably the most common configuration of coupled machines in industry. In this type of alignment, the motor is almost always the moveable machine, and the pump is the stationary machine. In almost all cases, the pump is already piped up with suction and discharge flanges, which means it can move only slightly.

Flow Technical offers a comprehensive laser shaft alignment that is proven to eliminate the most common cause of machine vibration, making it the most effective method for coupling alignment. Proper coupling alignment increases mean time between failures, bearing and seal life, and decreases power loss

The Reverse Dial Indicator method of alignment is the most common type of alignment, and is recommended for most all installations. The reverse dial indicator method uses the relative measurement of the center lines of two opposing shafts. This method acquires two indicator readings across the coupling